Sinker EDM Machine Znc650

Basic Info.

| Model NO. | ZNC650 |

| Performance Classification | Economical CNC Machine Tools |

| Certification | CE |

| Condition | New |

| 2ND Z Axis Travel | 260mm |

| Net Weight of Machine | 2100kgs |

| Distance From Electrode to Table | 340-800mm |

| Oil Load Capacity of Table | 1320×800×500mm |

| Travel of X/Y/Z | 600×500×200mm |

| Max. Machining Current: 50A | Z Axis Nc Control |

| Transport Package | Plywood Cae |

| Specification | CE |

| Trademark | Kingred |

| Origin | Jiangsu Province, China |

| HS Code | 8456301010 |

| Production Capacity | 300sets/Year |

Product Description

Sinker EDM ZNC650

Advantages of the product

Original Taiwan C-Tek controller, LCD monitor, Industrial Computer Controller.

High accuracy X, Y, Z three axes C3 grade Taiwan made ball screw

Z axis imported Japanese Sanyo servo motor control

Three axes DROs of 0.005mm resolution

Resin sand casting as machine body and inner stress removed to make sure long-time rigidity and stability.

Z axis is equipped with high precision roller guideway with Japanese SANYO DC servo motor, to make movement of Z axis more sensitive and smoother.

Machine has wide machine base to make sure machine is strong enough of heavy loading, X

and Y axis have V shape and flat guideway with FEFLON wear-resisting sticker, movement of

heavy load is smooth and light, no crawling phenomenon.

Working lamp, fire extinguisher and lubrication unit, and patented electrode holder are all Taiwan made.

ZNC die sinking EDM has X and Y axis manual control and Z axis program control, with handwheel of X and Y axis, it is fast and convenient to locate position for spark discharge machining. Due to affordable cost and good performance, ZNC EDM is widely used in producing various plastic injection molds, such as home applications, electronic connectors, powder metallurgy, automotive molds, and other industries.

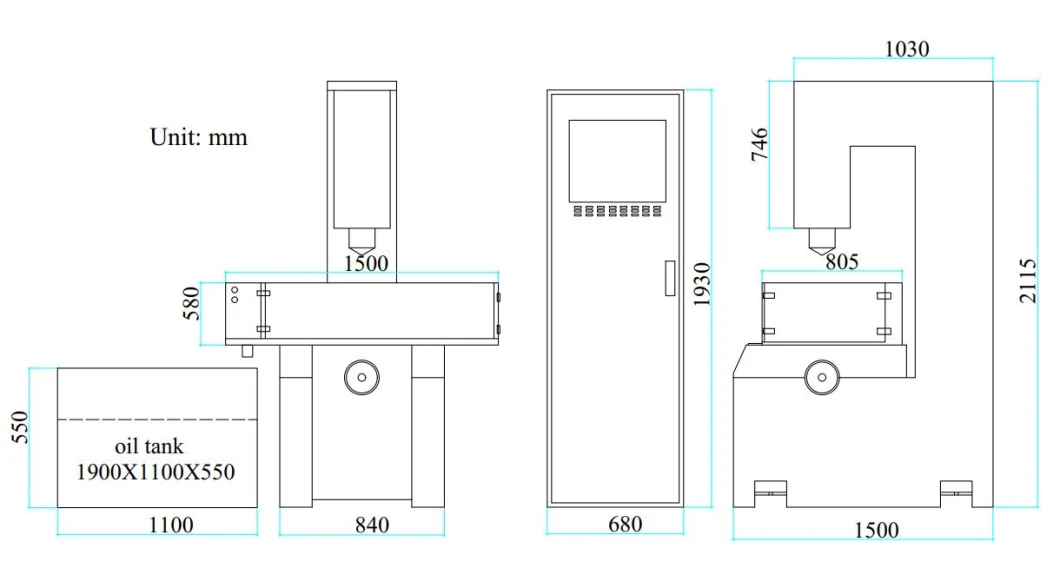

Main dimension of ZNC600:

X×Y×Z travel:600×500×220mm;

Working table dimension:900×500mm;

Working tank on table: 1320×800×500mm

Technical Parameters of ZNC EDM Sinker ZNC650

| Items | unit | ZNC650 |

| Oil load capacity of table | mm | 1320×800×500 |

| Table size | mm | 900×500 |

| Travel of X/Y/Z | mm | 600×500×220 |

| 2nd Z axis travel | mm | 260 |

| Distance from spindle end to table | mm | 340-800 |

| Oil tank dimension | mm | 1100×1900×510 |

| Max load of electrode weight | Kg | 50 |

| Load of table | Kg | 1000 |

| Dimension of machine | mm | 2500×1900×2350 |

| Net weight of machine | Kg | 2100 |

Power supply unit of ZNC controller

| Capacity | 50A | 75A | 100A | |

| Control Method and Axes | Close Loop (Z-axis) | |||

| Min. Setting Unit | 0.005mm(0.001mm) | |||

| Max. Setting Unit | 9999.995mm(9999.9999mm) | |||

| Coordinate System | INC,ABS | |||

| Display System | 15"LCD | |||

| Control System | PC BASED | |||

| Inching | 0.005mm(Unit)×1, ×5, ×10 | |||

| Data save | >10000 | |||

| Max. Machining Current | A | 50 | 75 | 100 |

| Total Power input | KVA | 4.5 | 6 | 10 |

| Max. Material Removal Rate | mm3/min | 360 | 560 | 700 |

| Electrode Wear Rate | % | <0.2 | ||

| Best Surface Finish | μm | Ra 0.35(Ra0.2 with special circuits) | ||

| Overall dimension | mm | 790×820×1850 | ||

| Net weight | kgs | 260 | ||

Main performance and technical specifications

1. The highly rigid, fine-grained cast iron machine base, column, table, and Meehanite cast iron components provide stability and long service life.

2. Spindle adopts DC servo to drive high precision ball screw, which enhances high accuracy and high quality.

3. Slideways coated with Turcite B anti-friction material, which ensures accurate and smooth traversing.

4. The slideways of X, Y axes are made up of V type structure; squareness and parallelism don't change.

5. The table is treated with high frequency hardening treatment and polished by precision grinding machine to ensure accuracy and service life.

6. 60 pages of files storage capacity provided, which can save 60 different moulds or customer numbers.

7. Provided with mirror machining circuit to be able to erode real mirror effect.

8. 10 sections auto finishing function, including(1)Self-editing Edit the machining condition according to personal experience.(2)Auto Z set: Just input the Z axis depth & current values, other machining data will preset automatically.;(3) Intelligent condition editing Just choose electrode shape, electrode and workpiece material, cross-section measure of electrode , finish type as well as depth setting, computer will edit machining condition automatically. Above three kinds of editing methods can be completed by rough→ medium→ fine at a time.

9. Machining condition can be modified during sparking.

10. Discharging condition will adjust automatically when discharging is unsteady, computer itself will amend discharging efficiency and work time. Discharging condition will recover automatically after its steady.

11. New fuzzy logic for arcing control and fuzzy servo voltage control: when the discharging is unsteady, machining parameter will be adjusted automatically. Moreover, electrode will raise back & up and pulse-off when arcing.

12. There are 3 kinds of coordinate systems: absolute coordinate, incremental coordinate and reference coordinate, to facilitate the mold alignment.

13. All new designed generator and 15'' screen can correspond with CE safety standard, which is dustproof, waterproof and anti-interference so as to prolong the service life of PC boards.

14. Generator adopts high stability industrial PC-based controller.

15. It has the sparking up function.

Function Characteristic Introduction of Control system

- . More than 20,000 units of programming storage capacity. Normally, more than 20,000 different programming of mold or customer numbering can be stored

- . With mirror surface processing circuit, a true mirror effect can be performed. Furthermore, it is even better to use orbital processing and powder mixing processing.

- . 10 segments auto editing function. Manual edit: edit machining condition by experience. AUTO Z auto edit: Max. Depths, initial current and finished process, machining area selection are provided, and then machining condition edit can be finished automatically. Intelligent condition edit electrode shape, electrode and workpiece material, workpiece section area and finished precision selection, depth setting area are provided, and then machining condition can be complete at a time by the way of rough→moderate→fine.

- X, Y,Z axis coordinate are switch with Metric and English system

- . If machining is unstable, discharging condition is auto adjusted by modifying discharging efficiency and working time. After that, the condition will restore automatically. And it is also adjustable at any time.

- . Auto arcing detecting function, if unsteady caused by arcing occurs, computer will adjust machining parameters and rise jump up height, then normal condition would return.

- . If could set that after 2~10 times discharging (jumping up control), the electrode will be raised (safe height Z) to the set arbitrary position and continue machining. This could achieve good slagging off performance for deep hole machining.

Function Characteristic Introduction of Control system

- . More than 20,000 units of programming storage capacity. Normally, more than 20,000 different programming of mold or customer numbering can be stored

- . With mirror surface processing circuit, a true mirror effect can be performed. Furthermore, it is even better to use orbital processing and powder mixing processing.

- . 10 segments auto editing function. Manual edit: edit machining condition by experience. AUTO Z auto edit: Max. Depths, initial current and finished process, machining area selection are provided, and then machining condition edit can be finished automatically. Intelligent condition edit electrode shape, electrode and workpiece material, workpiece section area and finished precision selection, depth setting area are provided, and then machining condition can be complete at a time by the way of rough→moderate→fine.

- X, Y,Z axis coordinate are switch with Metric and English system

- . If machining is unstable, discharging condition is auto adjusted by modifying discharging efficiency and working time. After that, the condition will restore automatically. And it is also adjustable at any time.

- . Auto arcing detecting function, if unsteady caused by arcing occurs, computer will adjust machining parameters and rise jump up height, then normal condition would return.

- . If could set that after 2~10 times discharging (jumping up control), the electrode will be raised (safe height Z) to the set arbitrary position and continue machining. This could achieve good slagging off performance for deep hole machining.

- . Function of avoiding second discharging and carbon desposition rapid raising or discharging boundary searching rapid rising.

- . Power control (equal energy) function for homogenizing machining effect. And this function could be switched off to accelerating graphite electrode machining.

- . Generator new design conforms to power supply box and 15-inch LCD display criterion of European CE safety regulation, which it is dustproof, waterproof, electric noise-proof and circuit board life could also be raised.

- . Industrial class PC-based controller is applied, and traditional hard disk is substituted by new DOM type memory, which enables faster and more steadily speed of file reading and it is more suitable for industry application.

- . Up discharging (reverse machining) function makes special machining easier.

- . Two independent machining coordinates. The male die and female die could be parted or machined in different coordinates.

- . After power off, system restarts and automatically reloads previous machining condition and coordinate of last time, so discharging could be finished by pushing remote control box without panel operation

- . Two jump up speed type, which serve speed could be raised when no electrode deformation and big area machining efficiency could also be raised.

- . Separately storage of coordinate and machining data, and same machining condition could be rapid added in different part machining.

- . Two high voltage circuits could be set in partial voltage or partial current according to customer's need

- . Arcing detection setting function could start carbon desposition hardware detecting circuit, and every charging pulse could be detected and current will be cut off when abnormal pulse occurs. So no short circuit is caused by shoot circuit

- . Discharging high voltage pulse control, which enables the settings of different high voltage pulse type and it could go with machining speed and electrode wear.

Sinker EDM ZNC650

EDM machining is electrode and workpiece are submerged into electrolytic working fluid, and respectively connected to cathode and anode of HF power source. When electrode approach to workpiece to a tiny and certain distance, electrical discharging happens, at the same time, high temperature erase release super high heat to erode workpiece.

Kingred's sinker EDM ZNC650 is featured in strong function, convenience and reliable operation; Machine is designed according to analyses of resistance to draw, resistance to press and reaction by computer. Casting is used FC-35 by national weathering and all kinds of treatment, it wears well and its precision is changeless. Machine structure is reasonable without distortion, of good rigidity to insure process precision. Rails are "V" shape, can move lightly under heavy load and good precision Z axis is used Japanese "SANYO" DC servo motor. High precision bears, the working table are used rails with "TAFULO" face. Danish "GRUNDFOS" oil pump or Italy "GALPEDA" oil pump. Three axes SINO grating ruler. Can arbitrarily choose the methods of removing scrap iron, sweeping oil or sucking oil, also choose process that the work piece is not submerged in oil. It suits to process cavity, holes and special shape parts in copper, steel.. Lubricating system is used callback way, lubrication of rail is completed once, and retains cleanness of appearance.PCB boards is moisture proof, anticorrosive, gold-filled.

Function Characteristic Introduction of Control system

1. More than 20,000 units of programming storage capacity. Normally, more than 20,000 different programmings of mold or customer numbering can be stored

2. With mirror surface processing circuit, a true mirror effect can be performed. Furthermore, it is even better to use orbital processing and powder mixing processing.

3.10 segments auto editing function. Manual edit: edit machining condition by experience. AUTO Z auto edit: Max. Depths, initial current and finished process, machining area selection are provided, and then machining condition edit can be finished automatically. Intelligent condition edit: electrode shape, electrode and workpeice material, workpiece section area and finished precision selection, depth setting area are provided, and then machining condition can be complete at a time by the way of rough→moderate→fine.

4. X,Y,Z axis coordinate are switch with Metric and English system

5.If machining is unstable, discharging condition is auto adjusted by modifying discharging efficiency and working time. After that, the condition will restore automatically. And it is also adjustable at any time.

6.Auto arcing detecting function, if unsteady caused by arcing occurs, computer will adjust machining parameters and rise jump up height, then normal condition would return.

7.If could set that after 2~10 times discharging(jumping up control), the electrode will be raised(safe height Z) to the set arbitrary position and continue machining. This could achieve good slagging off performance for deep hole machining.

8.Function of avoiding second discharging and carbon desposition rapid raising or discharging boundary searching rapid rising.

9.Power control(equal energy) function for homogenizing machining effect. And this function could be switched off to accelerating graphite electrode machining.

10.Generator new design conforms to power supply box and 15 inch LCD display criterion of European CE safety regulation, which it is dustproof, waterproof, electric noise-proof and circuit board life could also be raised.

11.Industrial class PC-based controller is applied and traditional hard disk is substituted by new DOM type memory, which enables faster and more steadily speed of file reading and it is more suitable for industry application.

12.Up discharging(reverse machining) function makes special machining easier.

13.Two independent machining coordinates. The male die and female die could be parted or machined in different coordinates.

14. After power off, system restarts and automatically reloads previous machining condition and coordinate of last time, so discharging could be finished by pushing remote control box without panel operation

15.Two jump up speed type, which serve speed could be raised when no electrode deformation and big area machining efficiency could also be raised.

16.Separately storage of coordinate and machining data, and same machining condition could be rapid added in different part machining.

17.Two high voltage circuits could be set in partial voltage or partial current according to customer's need

18.Arcing detection setting function could start carbon deposition hardware detecting circuit, and every charging pulse could be detected and current will be cut off when abnormal pulse occurs. So no short circuit is caused by shoot circuit

19.Discharging high voltage pulse control, which enables the settings of different high voltage pulse type and it could go with machining speed and electrode wear.