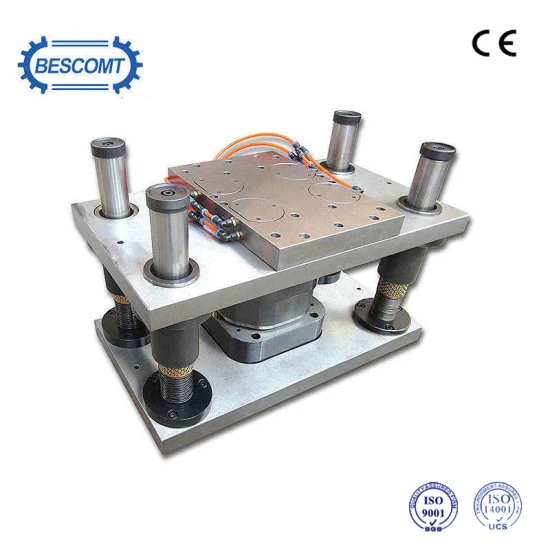

Roller Bearing Seat Mould/Mine Conveying Machinery Parts Mould

Basic Info.

| Model NO. | dm-08 |

| Manufacturing Technology | Computer Technology |

| Driving Motor Type | Permanent Magnet |

| Mold Cavity Technology | CNC Milling |

| Milling Speed | High Speed |

| Parts Detection Method | Measurement of Three Axis NC |

| After-sales Service | Remote Technical Guidance |

| Transport Package | Mold Wooden Case or Custom |

| Specification | Customized according to customer needs |

| Trademark | dongmo |

| Origin | Hebei, China |

| HS Code | 8480490000 |

| Production Capacity | 2600 Sets/Year |

Product Description

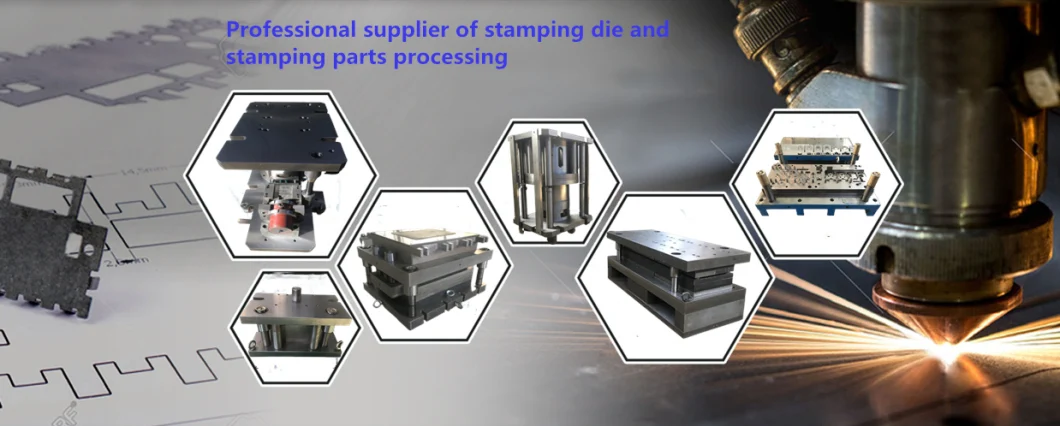

Product DescriptionFor the cover stamping die, we use the composite die structure to manufacture the die, saving the equipment resources, improve the production efficiency. Mold material selected high quality die steel. At the same time, we will customize the mold material and mold structure according to customer's requirements. Our company can realize the rapid release of parts of the mold, mold life up to 500,000 punch.

| Product name | Roller bearing seat mould |

| Application | Conveyor equipment |

| Material | Q235 |

| Standard Parts | MISUMI |

| Template flatness | +/-0.005mm |

| Quantity | 1 set |

| Package | According to customer requirements |

1. What information should the customer provide to get our accurate quotation?Customer should provide relevant technical requirements, drawings, pictures, industrial voltage, planned output, etc.2. What is the payment period?Payment terms are 40% deposit, 60% before delivery (T/T model).3. What is the delivery time?Delivery time of machines is 30-60 days after receipt of deposit.4. Do you test all the goods before delivery?Yes, we have 100% tests before delivery.5. Where is your factory? How do I get there?Our factory is located in Hengshui, Hebei Province, China. Warmly welcome domestic and foreign customers to patronize!6. What material is your mold made of?The materials are D2, YG15, DC53, SKD11, D2, SKH-9 and SKH-517. What is the biggest pressure in your factory?I plant 25T, 35T, 45T, 60T, 80T, 110T, 160T punch.8. What about the machinery in your factory?Our factory has a full set of processing equipment, including large CNC machining center, Sodic EDM machining, imported EDM-HS, radial drilling machine, milling machine, grinding machine, three-dimensional testing, etc.9. How does your factory conduct quality control?Quality comes first. The METS place a strong emphasis on quality control from start to finish. All of these are measuredperiodically by QC using three-dimensional measuring equipment.