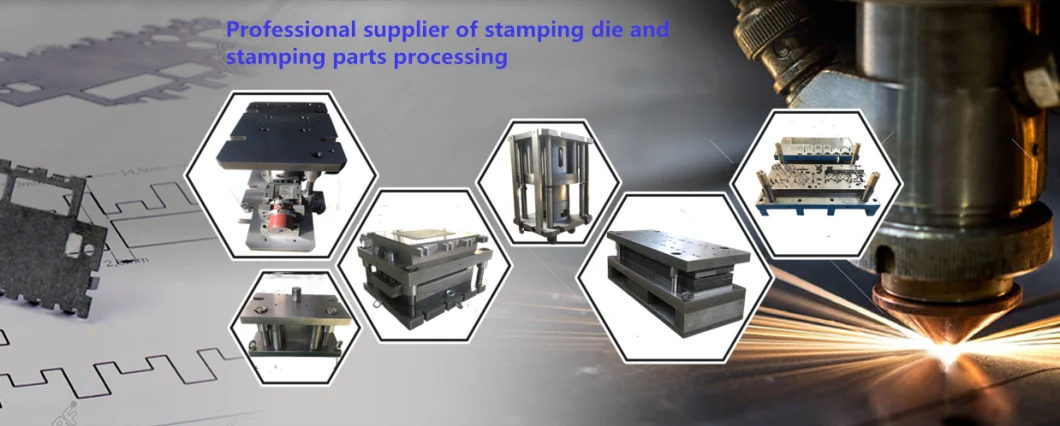

Professional Provision of Caster Brake Support Parts Continuous Stamping Die

Basic Info.

| Model NO. | DM0294 |

| Manufacturing Technology | Computer Technology |

| Driving Motor Type | Permanent Magnet |

| Mold Cavity Technology | CNC Milling |

| Milling Speed | High Speed |

| Parts Detection Method | Measurement of Three Axis NC |

| After-sales Service | Remote Technical Guidance |

| Mold Installation Method | Stationary Die |

| Quotation Method | Quote on Actual Order |

| Customization Mode | to The Drawing to The Sample Customization |

| Transport Package | Wooden Case or Custom Made |

| Specification | Customized according to customer needs |

| Trademark | dongmo |

| Origin | Hebei, China |

| HS Code | 8480490000 |

| Production Capacity | 2600 Sets/Year |

Product Description

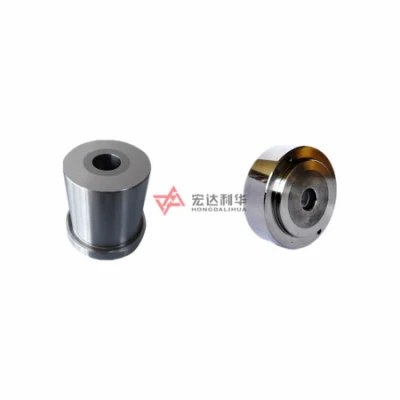

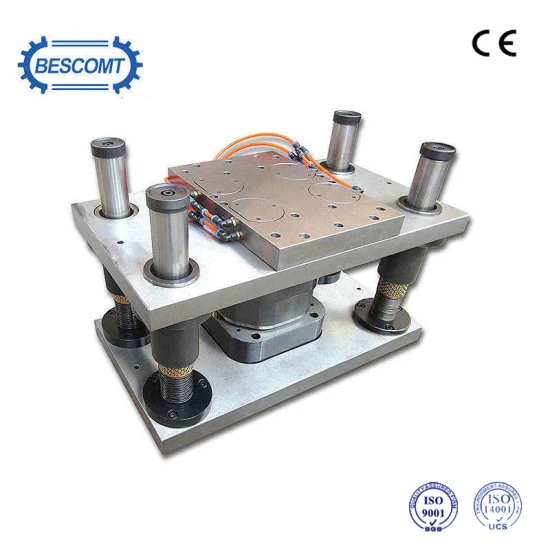

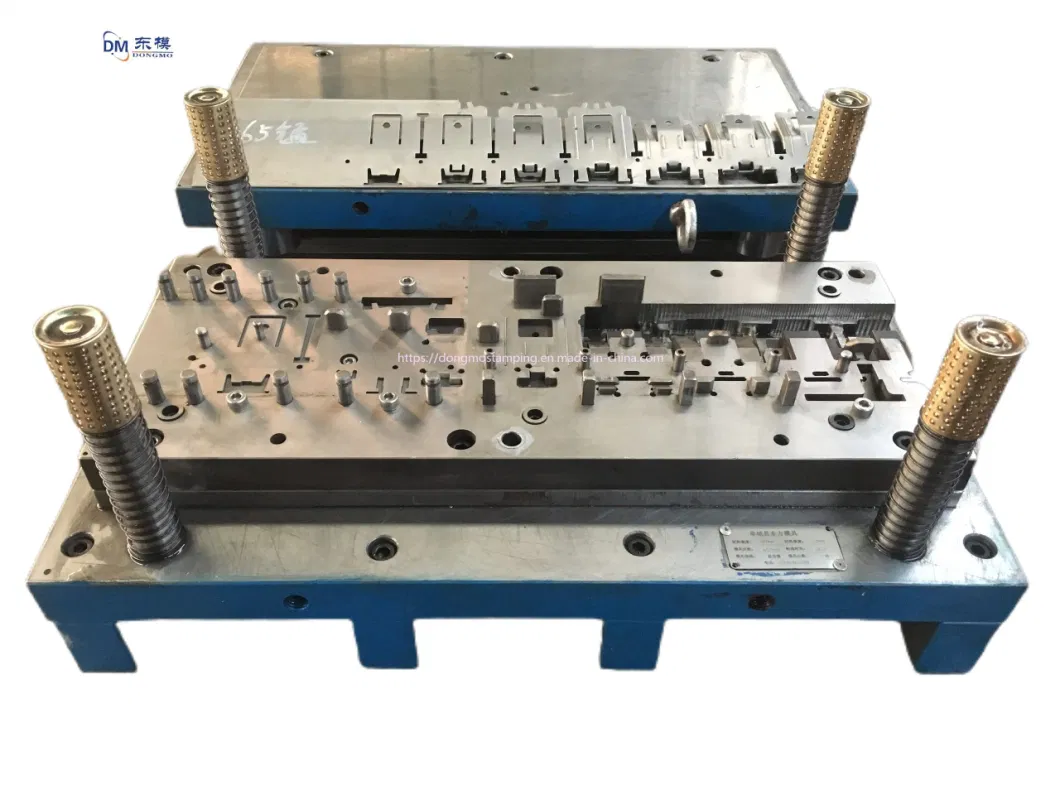

Product DescriptionCasters are mainly used in wheelbarrow, mobile scaffolding, workshop freight car and so on.Casters are constructed of a single wheel mounted on a bracket for mounting under the device to move it. There are two main categories of casters:A. Fixed casters: The fixed bracket is equipped with a single wheel and can only move in a straight line.B. Movable casters: the 360-degree steering bracket is equipped with a single wheel, which can drive in any direction at will.Automatic caster stamping die is also called continuous stamping caster die. This die has high efficiency and high precision, and the service life of the die is 1 million pieces. The die is sold at home and abroad. The caster continuous stamping mold can realize quick disassembly and change of molds. Each set of molds is equipped with four guide posts, and the accuracy of each guide post is 0.01mm. The wearing parts of the mould can also realize the quick disassembly structure. Welcome to visit the factory.

| Product name | Automatic caster stamping die |

| Application | hardware |

| Material | ST14-ST16S |

| Standard Parts | MISUMI |

| Template flatness | +/-0.005mm |

| Quantity | 1 set |

| Package | According to customer requirements |

| Application field | Aviation, automobiles, home appliances, medical, hardware, construction, |

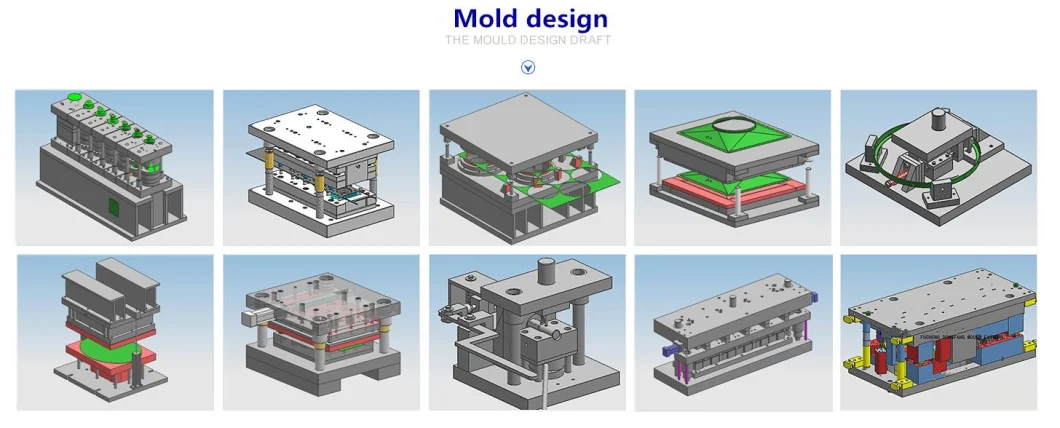

Mold processing equipment: CNC machining center, CNC wire cutting machine tool, CNC electric spark forming machine tool, turning, milling, grinding and other high-precision processing equipment.

Stamping equipment: 630T, 500T, 315T, 200T, 160T, 100T stretch forming hydraulic press and various large, medium and small tonnage punches.

Cutting equipment: 2D CNC laser cutting machine, 3D CNC laser cutting machine.

quality assurance

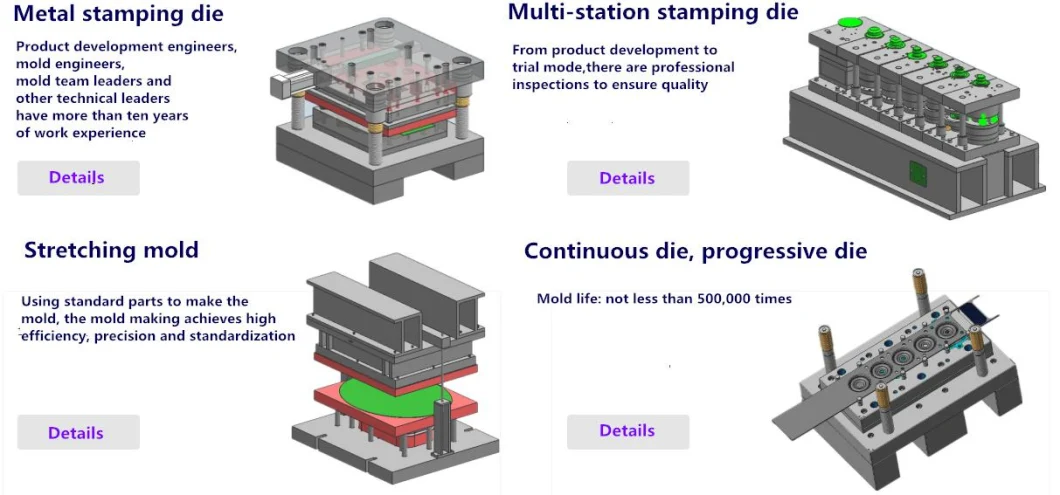

1. Product development engineer, mold engineer, mold leader and other technical leaders have more than 10 years of work experience

2. From product development to mold test, there are professional personnel to ensure the quality

3. Standard parts are used for mold making, and mold making is efficient, accurate and standardized

4. Mold life: no less than 500000 times

5. The company has passed the ISO9001:2008 international quality system certification.

FAQ

1. What information should the customer provide to get an accurate quotation from us?Customer should provide relevant technical requirements, drawings, pictures, industrial voltage, planned output, etc.2. What are the payment terms?Payment term is 40% down and 60% before delivery (T/T model).3. What is the delivery time?The delivery time of the machine is 30-60 days after receipt of the deposit.4. Why should you buy from us instead of other suppliers?1) We are a manufacturer of competitive price products for trading companies.2) We have more than rich manufacturing experience.3) Produce according to customers' requirements and products.