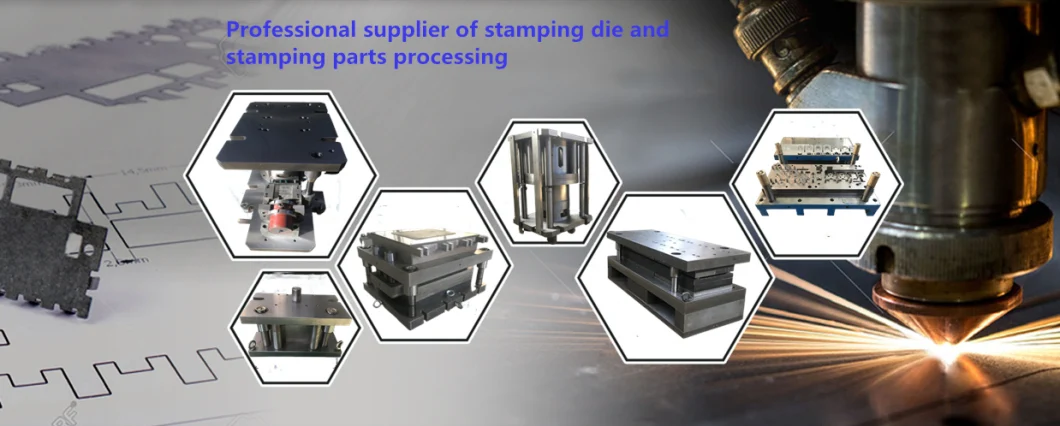

Mining Seal Idler Stamping Bearing Die for Conveying Machinery

Basic Info.

| Model NO. | DM0234 |

| Processing Method | Forming Mould |

| Technics | Drawing Die |

| Process Combination | Single-Process Mould |

| Manufacturing Technology | Computer Technology |

| Driving Motor Type | Permanent Magnet |

| Mold Cavity Technology | CNC Milling |

| Milling Speed | High Speed |

| Parts Detection Method | Measurement of Three Axis NC |

| After-sales Service | Remote Technical Guidance |

| Quotation Method | Quote on Actual Order |

| Action Object | Metal |

| Mold Installation Method | Stationary Die |

| Surface Treatment | on-Demand Processing |

| Transport Package | Mold Wooden Case or Custom |

| Specification | Customized according to customer needs |

| Trademark | dongmo |

| Origin | Hebei, China |

| HS Code | 8480490000 |

| Production Capacity | 2600 Sets/Year |

Packaging & Delivery

Package Size 850.00cm * 600.00cm * 660.00cm Package Gross Weight 375.000kgProduct Description

Product Description

Bearing block roller stamping die is completed by 7 sets of die. First of all, the material is put into the mold for the first stamping blanking - one pull - two pull - three pull - shaping - cutting - round hole punching.Our bearing moulds can be customized to various specifications, such as 204/205/206/305/306, etc. The bearing seat stamping die is suitable for use on the press, and can also be used on the oil press. Our molds can also be made into continuous stamping, which can be customized according to customer requirements.

| Product name | Roller bearing seat mould |

| Application | Conveyor equipment |

| Material | Q235 |

| Standard Parts | MISUMI |

| Template flatness | +/-0.005mm |

| Quantity | 1 set |

| Package | According to customer requirements |

Detailed Photos

Company Profile

Certifications

Sample display

Oriental Mould is engaged in metal stamping mould, drawing mould, molding mould, daily necessities mould, household appliance mould, tableware kitchenware mould, mechanical mould, cake mould mould, large special-shaped

Tensile and other hardware mold development and manufacturing mold, stamping processing.

Packaging & Shipping

FAQ

1. What information should the customer provide to get our accurate quotation?Customer should provide relevant technical requirements, drawings, pictures, industrial voltage, planned output, etc.2. What is the payment period?Payment terms are 40% deposit, 60% before delivery (T/T model).3. What is the delivery time?Delivery time of machines is 30-60 days after receipt of deposit.4. Do you test all the goods before delivery?Yes, we have 100% tests before delivery.5. Where is your factory? How do I get there?Our factory is located in Hengshui, Hebei Province, China. Warmly welcome domestic and foreign customers to patronize!6. What material is your mold made of?The materials are D2, YG15, DC53, SKD11, D2, SKH-9 and SKH-517. What is the biggest pressure in your factory?I plant 25T, 35T, 45T, 60T, 80T, 110T, 160T punch.8. What about the machinery in your factory?Our factory has a full set of processing equipment, including large CNC machining center, Sodic EDM machining, imported EDM-HS, radial drilling machine, milling machine, grinding machine, three-dimensional testing, etc.9. How does your factory conduct quality control?

Quality comes first. The METS place a strong emphasis on quality control from start to finish. All of these are measured periodically by QC using three-dimensional measuring equipment.