Bottom Ring Forming Dies and Molds for LPG Gas Cylinder Production Line

Basic Info. Model NO.:LPG cylinder foot ring moldsDriving Motor Type:Permanent MagnetMold Cavity Technology:EDM MillingM

Basic Info.

| Driving Motor Type | Permanent Magnet |

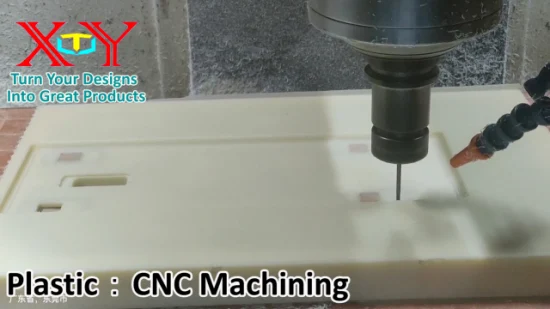

| Mold Cavity Technology | CNC Milling |

| Milling Speed | Normal Speed |

| Parts Detection Method | Measurement of Three Axis NC |

| Transport Package | Exportable Wooden Box |

| Specification | Customized Size |

| Origin | China |

| Production Capacity | 10000 Pieces/Year |

Product Description

Basic Info.Model NO.:LPG cylinder foot ring moldsDriving Motor Type:Permanent MagnetMold Cavity Technology:EDM MillingMilling Speed:Normal SpeedParts Detection Method:Measurement of Three Axis NCTransport Package:Exportable Wooden BoxSize:customizedTrademark:GETWELDOrigin:ChinaHS Code:8207209000Production Capacity:10000 pieces/Year

Product DescriptionNormally LPG cylinder foot ring is formed with processes as below:

1.Steel coil de-coiling and flattening 2. blanking and roll stamping 3.Circling and edge bending 4. Linear welding

The whole set of foot ring dies mainly contain the blanking mould, , the circling and edge bending mould, the linear welding

Mold material descriptionBlanking mold

| Heat treatment | one quenching + two tempering | Punch | Dc53 |

| Template material | A3 | Die | DC53 |

| Punch plate and fixed plate | 45# | Lateral plate | Cr12 |

| Heat treatment | one quenching + two tempering | Inner core | Cr12Mov |

| Template and pad material | A3 | Retainer | Cr12 |

| Upper die | Cr12Mov |

Send to us